Page 3 of 10

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Sat Feb 28, 2015 10:53 pm

by JPG

10 min tops to reassemble!(closer to 5)

Took longer to post with the new forum software than disassembly and pix taking.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Wed Mar 04, 2015 2:26 pm

by br549

Another favor of the community please ... does anyone have a Parts List and Exploded Parts Diagram for a manual feed planer? In the process of adding the feed pinion to my cart to buy, other "suggested" parts appeared which look to be some of which I need, but I'm not 100% sure, as Shopsmith only shows me a Part Number and a price, but no picture. I have sent my question to Shopsmith CS for verification, but while waiting for a response perhaps someone else could help. Attached is one of the photos which JPG took and posted, to which I have added clouds and PRESUMED part numbers. If I really can get these thru Shopsmith, that much less to have to invent or improvise!

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Wed Mar 04, 2015 2:59 pm

by admin

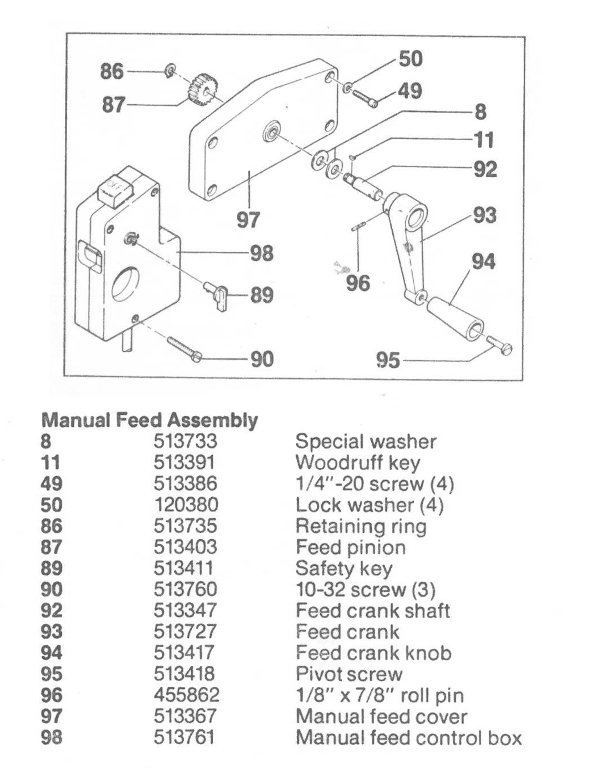

- manual_feed_planer.jpg (60.66 KiB) Viewed 15906 times

Here is a scan from an old manual. Verification of items with customer service is recommended, since changes can be made to parts over time.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Wed Mar 04, 2015 6:26 pm

by JPG

Admin has provided the original part #.(kudos for that!).

I really think a 3/8" straight shaft will be easier than the stepped shaft. The shaft can be stepped up with bushings where required. Since you will be making the cover bushing, it can be 3/8" to fit the shaft. The pinion gear will fit the 3/8" shaft. A different way to key it to the gear would be needed.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Thu Apr 09, 2015 9:55 am

by br549

Time for an update. I ordered what parts I could, along with a few other missing necessities like Owner's Manual, knife setting gauge, power coupler, etc. Thanks to Admin for posting the parts diagram. Not having to make the shaft or pinion gear was a real time saver, and the cost was surprising low for these parts. For the cover and bushing, I bolted a 1/8" thick piece of steel to the inside of the cover and drilled a hole matching the OD of bushings, which I had salvaged from my old garage door opener. One bushing had to be shortened slightly, but it had the necessary "shoulder" to butt up against the steel plate. Made another 1/8" thick steel filler with OD to fit inside of the hole in the cover and with an ID matching OD of bushing. Initially thought and tried assembling all the parts "dry", but fit was too loose and too much wobble in crank handle. Used JB Weld to attach bushings to each other and to steel plate. Used 1/2" bolt with Scotch tape around un-threaded portion of bolt to align all of the parts until the JB Weld had set up enough to allow bolt removal. Made crank handle and clamp brackets out of some very dense SYP. (Clamp bracket from Speed Reducer used as template.) Carriage bolt with slot cut in head for screwdriver, filed off square portion under head used to attach wood handle, and a few washers to control amount head was recessed. Lock nut keeps carriage bolt from trying to unthread as crank is turned. Have checked knife alignment and adjusted table height mechanism, so almost ready to try planing!

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Thu Apr 09, 2015 10:50 am

by dusty

I certainly hope that it works as well as it looks. You have done a fantastic job.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Thu Apr 09, 2015 8:52 pm

by JPG

I totally agree with Dusty!!!

I am surprised the shaft was still 'available'.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Fri Apr 17, 2015 4:38 pm

by burnt

Has anyone found any good guidance on what to do about the feed motor if running the powerpro off 220V? I'm planning to switch over to get that extra 1/4hp, but it seems like this would be a problem when it comes to the feed motor. I guess I could just plug the feed motor into a 110V outlet, but I've been waffling on whether to keep the planer or just sell it.

Good thing manual feed is dual-voltage.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Fri May 01, 2015 9:28 am

by burnt

No one's going to touch on that one, it seems. I can't seem to find an answer in powerpro documentation, so I might try calling CS to ask for directions for once.

Re: Can a 12" Planer w/o feed motor be converted to manual feed?

Posted: Fri May 01, 2015 9:44 am

by dusty

dusty wrote:I certainly hope that it works as well as it looks. You have done a fantastic job.

I went back and reread this thread and I have to correct one of my previous comments. Fantastic is inadequate. You have done an unbelievably good job on this. Even the JB Weld application looks professional.

Now, the other big question. How does it work?