Page 1 of 2

Repairing Model 510 Castings, A Question

Posted: Fri Jun 07, 2019 4:07 pm

by dusty

I have a set of 510 castings that have been countersunk every where that Shopsmith would have used a pan head.

I want to use these for my Adjustable Height Work Bench and preserve the ones I have there now (seen in a couple recent posts).

My Question: Will JB Welb be an appropriate filler for these countersinks? I will need to redrill in order to install the legs. I am "considering" drilling the new holes offset from the existing ones.

Re: Repairing Model 510 Castings, A Question

Posted: Fri Jun 07, 2019 11:00 pm

by JPG

IIWM, I would first try screws with washer heads. The extra od will hopefully span the current csink od. If so I do not think much is gained by using the jb-weld.

Why the non-use of flat head screws???

I am assuming end castings. If not, what ones?

Re: Repairing Model 510 Castings, A Question

Posted: Fri Jun 07, 2019 11:42 pm

by everettdavis

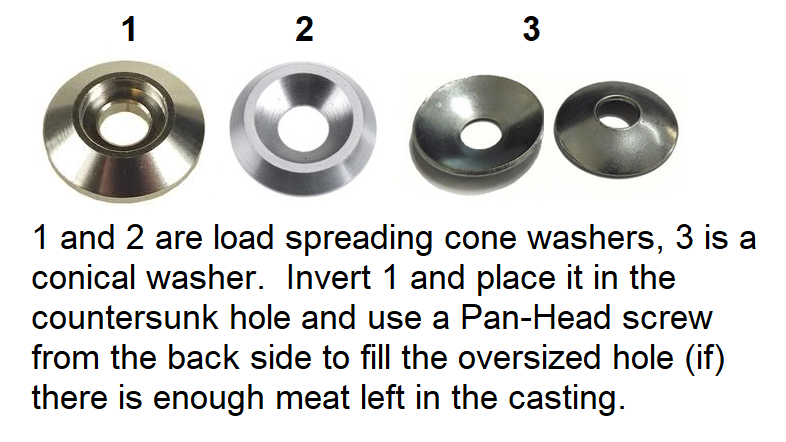

Search for cone washer and see if that won’t help you avoid filling the countersunk holes altogether

Everett

Re: Repairing Model 510 Castings, A Question

Posted: Sat Jun 08, 2019 7:38 am

by dusty

I don't like the appearance of the flathead screws in the countersunk holes. Furthermore, the countersinks in the castings (IMO) reduce the integrity of the material and I fear breakout when under stress. The countersinks were drilled too deep when they were done (I did not do these).

Don't know what I am going to do...but something. I will look into cone washers, Everett. Never heard of them before.

Re: Repairing Model 510 Castings, A Question

Posted: Sat Jun 08, 2019 8:14 am

by robinson46176

Do an image search on cone washers and also do an image search on trim washers.

You could also just use regular pan head screws (or even hex bolts) with flat washers but get both of them in chrome plate. It might make it look faster...

.

Re: Repairing Model 510 Castings, A Question

Posted: Sat Jun 08, 2019 9:43 am

by JPG

https://www.lowes.com/pd/Hillman-1-4-in ... nt/4756539

Not sure if jb-weld will greatly increase the the strength.

Which castings are relevant?

Re: Repairing Model 510 Castings, A Question

Posted: Sat Jun 08, 2019 12:33 pm

by dusty

[quote="JPG"]

https://www.lowes.com/pd/Hillman-1-4-in ... nt/4756539

Not sure if jb-weld will greatly increase the the strength.

Which castings are relevant?[/quote]

Those to which the legs are attached.

Re: Repairing Model 510 Castings, A Question

Posted: Sat Jun 08, 2019 5:39 pm

by everettdavis

dusty wrote:I don't like the appearance of the flathead screws in the countersunk holes. Furthermore, the countersinks in the castings (IMO) reduce the integrity of the material and I fear breakout when under stress. The countersinks were drilled too deep when they were done (I did not do these).

Don't know what I am going to do...but something. I will look into cone washers, Everett. Never heard of them before.

Cone washers can if proper size, fill the bevel and with a suitable fender washer allow a Pan Head screw to work. Yours apparently is now overly deep and too much metal was removed. I heard this once on a machine that a fellow bought the chrome screws on eBay. They were over-sized, requiring him to deepen the countersink depth. I never saw how it turned out.

Alternatively if you have or you know someone with a MIG welder with a spool gun, or a TIG you could fill the holes, then drill new ones as needed. If they over-drilled the holes cone washers will not add the strength you likely need in the casting as they just fill the countersink.

The graphic below represents what I was originally referring to by using the cone to fill the over-size hole with a pan head screw.

Everett

- Cone Washers.png (161.44 KiB) Viewed 19478 times

Re: Repairing Model 510 Castings, A Question

Posted: Sun Jun 09, 2019 8:19 am

by dusty

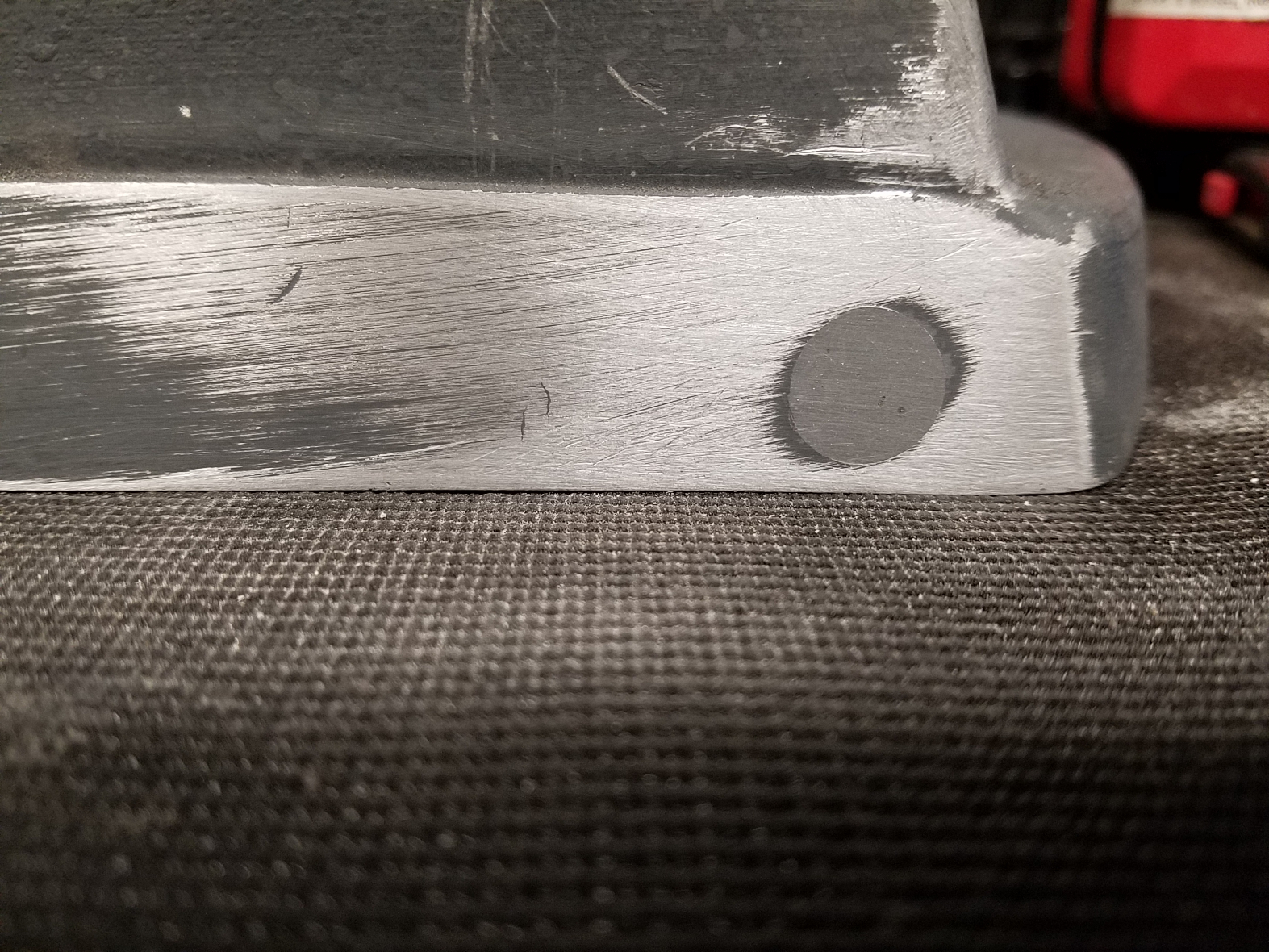

Thanks for the advise; however, I choose to do it my way.

It is too early to say that it works. It is even too early to say that I am done but a couple holes are nearly ready for paint. Just some prep work remaining.

I learned a couple things. Mix well and don't over fill. Also, JB Weld is self leveling.

- 20190609_044510.jpg (1.48 MiB) Viewed 19416 times

- 20190609_044538.jpg (1.54 MiB) Viewed 19416 times

- 20190609_044713.jpg (1.36 MiB) Viewed 19416 times

Re: Repairing Model 510 Castings, A Question

Posted: Sun Jun 09, 2019 9:21 am

by JPG

What does the inside look like?