Page 1 of 2

Today in the shop (a lift for the drill press)

Posted: Fri Nov 08, 2019 9:17 pm

by reible

This turned out to be less successful then I hoped but....

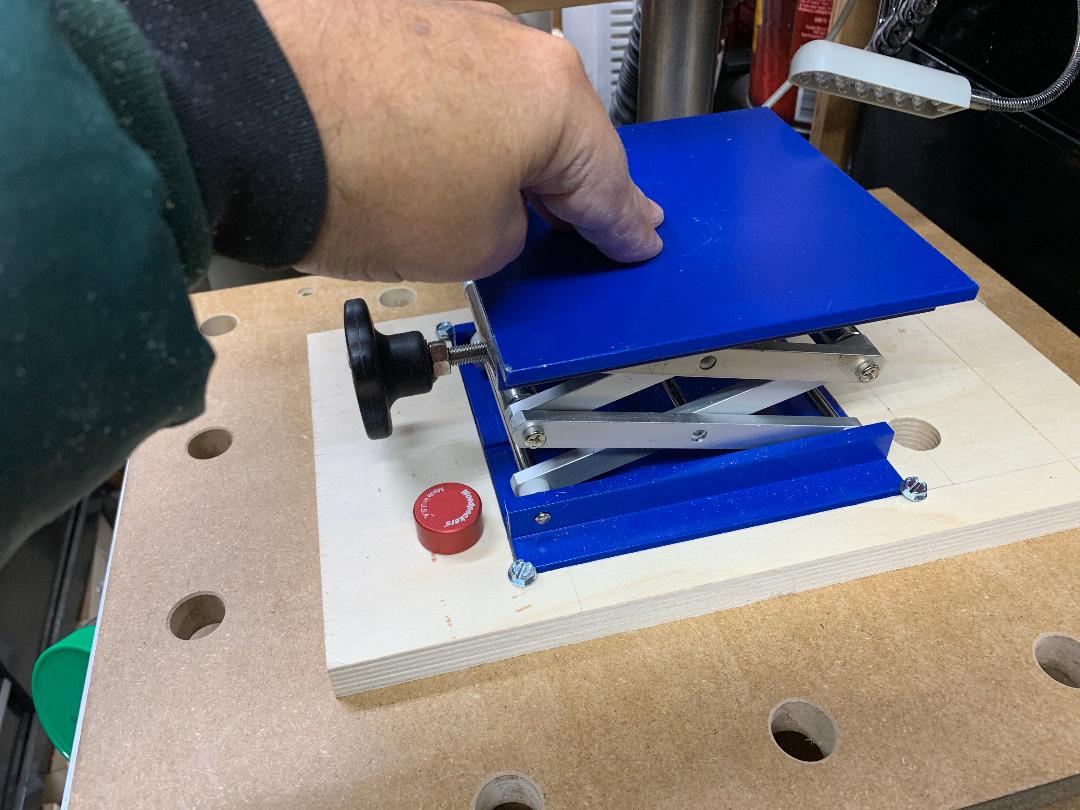

This is a small lift table that I had plans for. It is not as stable as I had hoped. You can get a small amount of compression when you press down on it. I have not measured it yet but I can see it move. In a lot of cases that will not matter but if you are trying to drill a hole to a certain depth, well it is going to be off by some amount.

- lift3.jpg (116.6 KiB) Viewed 13563 times

I have not made a sacrificial top for it yet but that will not be a big deal to do. My intention is using this only on smaller parts that don't require a fence or other location fixed points. The part could most likely be clamped to the top if needed but the intent is more for light weight use in wood and plastic and not metal.

It is designed to fit my drill press table using dogs for location and holding it in place.

- lift1.jpg (124.37 KiB) Viewed 13563 times

You simply turn the knob to go up and down. The lift goes from 2.2" to 10" but as I have it mounted it will set higher and again I have not measured that distance.

- lift2.jpg (130.2 KiB) Viewed 13563 times

And yes it can be located at 90 degree locations using the dogs. If you want a different rotation then some external clamping is required.

This has been on the back burner for a while due to the flex but perhaps someone will have an interesting idea how to fix that????

In the mean time I'm now working on making this usable with my SO to make a co-planer tape board to work piece.

Ed

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 7:41 am

by br549

reible wrote:This has been on the back burner for a while due to the flex but perhaps someone will have an interesting idea how to fix that????

How about 4 equal length dowels, one at each corner? Lower the platform to hold them in place. You could have an assortment of dowels in various lengths (inch increments for example).

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 8:09 am

by RFGuy

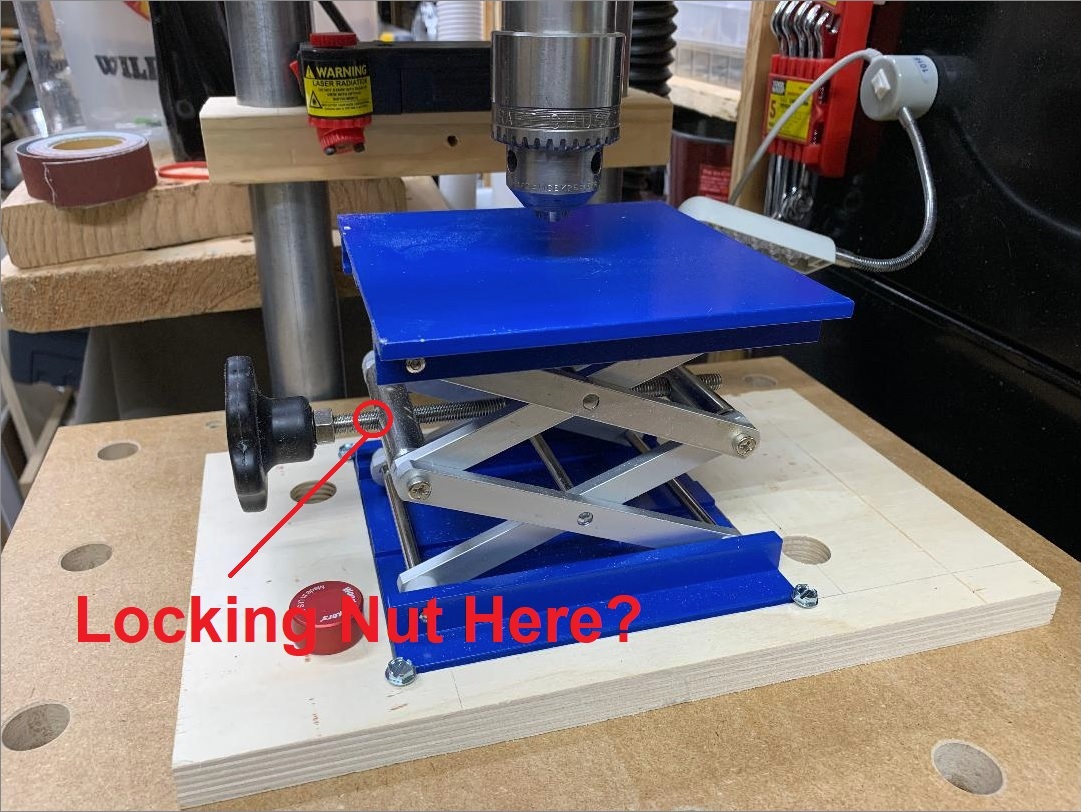

I haven't used these scissor lifts before, but just a couple of quick thoughts. Do you think the compression is coming from tolerances in the hinge pivots from the scissor members? Or is it possible that the height adjustment mechanism (threaded rod) has a bit of slop when you push down on the platform? If the latter, I was just wondering if there is some way to tighten up the locking mechanism for the height adjustment to avoid the compression...or possibly add a 2nd lock mechanism to hold the desired height. Possibly putting another nut on the threaded rod could be used as a locking nut when you are at the desired height.

- ScissorLift.jpg (286.27 KiB) Viewed 13514 times

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 9:28 am

by claimdude

Ed,

Very interesting indeed! Where did you get the scissor mechanism? I also have a SO and would be interested in updates on your proposed use of this with the SO.

Thanks

Jack

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 10:02 am

by masonsailor2

It looks like it is a gun rest. I have seen them at the range before.

https://www.amazon.com/Lyman-Bag-Jack-S ... B06Y2Y79HK

Paul

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 11:07 am

by reible

The flex seems to come from every where, no one place seems to be the issue.

These come in many many variations and the same principle is used as any scissor lift. Since the intent is to use these to lift things I think the design will always have some slop that goes away with load.

Pre-loading is one of the things I have though about. I have some free weights that I will try and see if that might be a solution. If as little as a few pounds works that would be great, but if it is like 10 pounds then it is getting iffy.

I got this one off Amazon, some where around $47 if I remember right. They have ones that are much cheaper and of course more expensive. I went sort of down the middle hoping for somewhat better quality, and less flex but there might be a better one out there if you could get your hands on them to test with.

I'm not sure I will have the work done for the SO version for a while. Winter has closed in on us and it just plain has been to cold to get much done. We are running at January level temperatures??? I did post over at the Shaper Community if you want to see how I think this will work. If you don't care to go there I can post here as well??

Ed

Re: Today in the shop (a lift for the drill press)

Posted: Sat Nov 09, 2019 9:16 pm

by claimdude

I will check out the SO community for your post there. Thanks Ed!

Re: Today in the shop (a lift for the drill press)

Posted: Sun Nov 10, 2019 11:22 am

by Ed in Tampa

I wonder if small springs connected to the end rods would preload it enough to take out the movement.

Re: Today in the shop (a lift for the drill press)

Posted: Sun Nov 10, 2019 12:20 pm

by rpd

I am not a shooter, but if you need a "bag lift" wouldn't it be easier to just wear briefs instead of boxers or going commando. .

Re: Today in the shop (a lift for the drill press)

Posted: Sun Nov 10, 2019 12:37 pm

by JPG

Ed in Tampa wrote:I wonder if small springs connected to the end rods would preload it enough to take out the movement.

Small springs with enough tension over the very large range of extension is unlikely easily obtained.

No, I do not have a better suggestion. I see this as unlikely being good enough for Ed. Even if all the slop is taken out of the pivots, there is still the two(pair) sliding ends flapping in the breeze so to speak. I perceive a possible twisting issue as well as loading movement.